OPTIC-4,gaschromatograhy and advantages

Key Takeaways:

- Introduction

- What is OPTIC-4?

- Principles of Gas Chromatography

- Key Features of OPTIC-4

- Advantages of Using OPTIC-4 with Gas Chromatography

- Applications of OPTIC-4 in Various Industries

- Future Trends in Gas Chromatography with OPTIC-4

Introduction to OPTIC-4 and Gas Chromatography

Understanding OPTIC-4

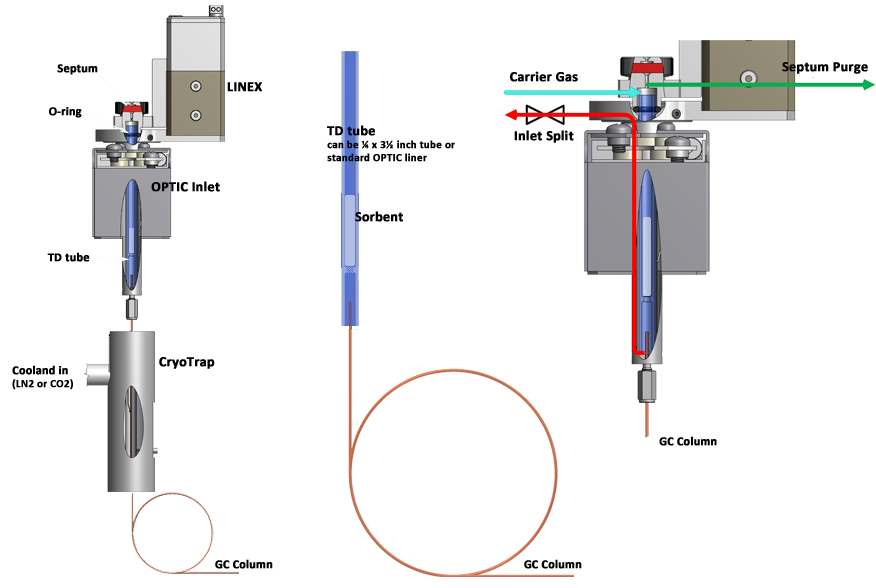

OPTIC-4 is an advanced and versatile thermal desorption system, designed to enhance the capability of gas chromatography. The system is engineered to optimize the efficiency and accuracy of volatile organic compound (VOC) analysis. By utilizing a unique four-stage configuration, this technology enables precise thermal desorption while minimizing sample biases that can affect analytical outcomes. The integration of OPTIC-4 in gas chromatography workflows signifies a step towards more robust environmental and medical analyses, fulfilling the industry's growing demands for high-performance analytical solutions.

What is Gas Chromatography?

Gas chromatography (GC) is a widely employed analytical technique utilized for the separation and analysis of compounds that can be vaporized without decomposition. At its core, GC leverages the properties of both liquid and gas phases to facilitate the separation of sample mixtures based on their volatilities. The sample mixture is first vaporized and then transported through a column where different components interact with the stationary phase. This interaction leads to a differential travel time for each compound, enabling qualitative and quantitative analysis. GC is notably effective in fields such as environmental monitoring, food safety, and the chemical industry.

Significance in Analytical Chemistry

The conjunction of OPTIC-4 with gas chromatography represents a significant milestone in analytical chemistry, allowing for enhanced accuracy and reliability in sample analysis. This system allows chemists to detect and quantify even the trace amounts of compounds, establishing its critical role in research and quality control. As researchers face increasingly complex samples, the ability to effectively separate and identify compounds with minimal interference becomes essential. In this context, the utilization of OPTIC-4 not only streamlines the process but also improves the validity of results.

Advantages of Combining OPTIC-4 with GC

The integration of OPTIC-4 into gas chromatography systems offers numerous advantages, including:

- Enhanced sensitivity: The efficient thermal desorption process ensures that minimum sample amounts are sufficient for accurate analysis.

- Increased throughput: OPTIC-4’s automation capability significantly reduces the analysis time, enabling higher sample volumes to be processed in shorter durations.

- Versatility: The capabilities of the OPTIC-4 system allow for the analysis of a wide range of sample types, including solids, liquids, and environmental samples.

- Improved reproducibility: Consistent thermal desorption minimizes variation across runs, leading to reliable data and enhanced method validation.

In conclusion, the emergence of technologies like OPTIC-4 in tandem with gas chromatography dramatically augments the analytics landscape, making it a pivotal tool in both research and industry. The advantages outlined not only elevate the standard of analytical quality but also foster innovation in exploring complex matrices. Stay tuned as we unravel more about the capabilities and insight offered by these groundbreaking developments in our upcoming sections.

What is OPTIC-4?

Overview of the OPTIC-4 System

The OPTIC-4 system represents a significant advancement in the field of gas chromatography. Designed to enhance the analytical capabilities of traditional gas chromatography systems, the OPTIC-4 allows users to perform multiple sample introduction techniques seamlessly and efficiently. Unlike conventional systems, the OPTIC-4 is characterized by its modular design, which offers flexibility in method development and application.

Key Design Features

The design of the OPTIC-4 is centered around versatility and user-friendliness, featuring an intuitive interface that facilitates easy operation. Key components include:

| Component | Function |

|---|---|

| Focusing Capillary | Directs the volatile components into the GC column with minimal loss. |

| Sample Injection Port | Allows for various introduction techniques such as liquid, gas, or direct transfer. |

| Thermal Control System | Ensures precise temperature management for improved reproducibility. |

| Integrated Software | Facilitates method optimization and data analysis, enhancing user experience. |

Working Mechanism

The OPTIC-4 works by utilizing a series of heating stages that allow for the optimal vaporization of samples before they enter the gas chromatograph. This process is crucial for accurate analysis, as it ensures that the sample components are adequately vaporized and available for separation within the column. The system’s capability to alternate between different modes—such as liquid injection, solid-phase microextraction (SPME), and headspace analysis—adds to its robustness and adaptability in various analytical scenarios.

Enhancements to Gas Chromatography Capability

One of the standout features of the OPTIC-4 is its potential to significantly enhance the performance of gas chromatography. The system enables:

- Improved Sensitivity: The precise thermal control maximizes analyte recovery, leading to more sensitive detection.

- Reduced Analysis Time: Rapid equilibration among heating stages decreases the time required for sample analysis.

- Diverse Applications: Adaptable for various applications including environmental analysis, forensic science, and pharmaceuticals.

In summary, the OPTIC-4 system revolutionizes the standard practices in gas chromatography by enhancing both method versatility and analytical performance. Its impressive design and operational functionality make it a powerful tool for laboratories seeking to optimize their analytical processes.

Principles of Gas Chromatography

Understanding the Separation Process

At the core of gas chromatography lies the principle of separation of compounds based on their volatility and interaction with the stationary phase inside the chromatographic column. The sample, usually in vapor form, is injected into a chromatographic column packed with a stationary phase. This process involves the movement of the mobile phase—typically an inert carrier gas like helium or nitrogen—which transports the sample through the column.

“The beauty of gas chromatography lies in its ability to separate complex mixtures and provide insights into their components, making it an indispensable tool in analytical chemistry.”

As the sample travels through the column, different components interact with the stationary phase at varying levels, leading to differential retention times. This separation effectively sorts the components based on their boiling points and affinities, allowing for precise analysis.

Detection Methods in Gas Chromatography

Following the separation, a detection method is employed to identify and quantify the components exiting the column. The two most commonly used detection methods include flame ionization detectors (FID) and thermal conductivity detectors (TCD).

An FID detects organic compounds by measuring the ions produced when the sample is combusted in a hydrogen flame. This method provides high sensitivity and is widely used for detecting hydrocarbons. In contrast, the TCD functions by measuring changes in thermal conductivity as different gases pass through a heated element. While less sensitive than FID, TCD offers the advantage of being applicable to both organic and inorganic compounds.

Factors Influencing Chromatographic Performance

Various factors influence the performance of gas chromatography, notably temperature, flow rate, and column dimensions. Maintaining optimal temperature control is critical, as it affects the volatility of the components and their interaction with the stationary phase.

Furthermore, the flow rate of the carrier gas can impact the efficiency of separation. A higher flow rate may reduce retention time but can compromise resolution, while a lower rate offers better resolution but may increase overall analysis time. Additionally, the choice of column dimensions (length, diameter, and packing material) plays a pivotal role in achieving desired selectivity and sensitivity during the analysis.

By understanding these fundamental principles of gas chromatography, analysts can better tailor their methods for effective separation and identification of compounds in complex mixtures. This expertise is crucial for researchers and professionals alike seeking to harness the power of this analytical technique in various fields, including environmental monitoring, pharmaceuticals, and food safety.

Key Features of OPTIC-4

Versatility Across Applications

The OPTIC-4 system is explicitly designed for versatility, accommodating a wide range of applications in the field of gas chromatography. One of its significant advantages is its ability to handle various sample types, including solid, liquid, and gaseous samples. This flexibility is essential for laboratories that deal with diverse substances, as it reduces the need for multiple systems and promotes efficient workflow.

Rapid Temperature Programming

Another standout feature of the OPTIC-4 is its rapid temperature programming. This innovative approach allows users to achieve optimal separation speeds while maintaining excellent resolution. The system can quickly adjust the temperature of the injection port, leading to increased throughput and improved analysis time. This is particularly beneficial in fast-paced research environments where timely results are crucial.

Integration with Various Detectors

The OPTIC-4 system excels in its capacity for seamless integration with various detectors, enhancing its analytical capabilities. Whether you require a flame ionization detector (FID), mass spectrometry (MS), or other specialized detectors, the OPTIC-4 can be configured to fit your needs. This flexibility not only broadens the scope of analyses that can be performed but also ensures that users can select the most appropriate detector based on their specific requirements.

User-Friendly Interface

Moreover, the user-friendly interface of the OPTIC-4 ensures that both expert and novice users can navigate the system with ease. The intuitive software allows for straightforward programming of methods, while comprehensive support and user guides enhance the overall experience. This accessibility plays a crucial role in minimizing training time and maximizing productivity in the laboratory environment.

Robust Performance

Finally, the robust performance of the OPTIC-4 is a testament to its quality engineering. Built to withstand the rigors of daily laboratory use, the system offers high reliability and consistently accurate results. Laboratories can trust that the OPTIC-4 will deliver the performance necessary to meet demanding standards in various analytical applications.

In conclusion, the OPTIC-4 system stands out in the field of gas chromatography due to its exceptional versatility, rapid temperature programming, seamless integration with detectors, user-friendly interface, and robust performance. These key features empower laboratories to conduct high-quality analyses for a wide range of applications, making the OPTIC-4 an invaluable asset in modern scientific research.

Advantages of Using OPTIC-4 with Gas Chromatography

Improved Sensitivity

One of the standout features of OPTIC-4 is its ability to enhance the sensitivity of gas chromatography analyses. By utilizing advanced thermal desorption technology, OPTIC-4 enables the detection of trace levels of compounds that might otherwise go unnoticed. This improvement is particularly beneficial in industries dealing with environmental monitoring and pharmaceutical analysis.

"The heightened sensitivity of OPTIC-4 allows analysts to meet stringent regulatory standards effortlessly."With the capability to discern minute differences in sample composition, researchers can gain deeper insights into their subject matter, leading to more accurate conclusions and better decision-making.

Faster Analysis Speed

The integration of OPTIC-4 significantly reduces the analysis time required for gas chromatography. This is largely due to its automated processes which streamline the entire analytical workflow. Traditional gas chromatography often involves labor-intensive steps that can delay results. However, with OPTIC-4, analysts experience a more efficient workflow that not only saves time but also increases productivity.

"Efficiency is key in research; with OPTIC-4, we have reduced our analysis times by over 30%!"By minimizing downtime and allowing for quicker turnarounds, labs can handle more samples simultaneously without compromising the quality of their results.

Enhanced Sample Handling

When it comes to sample handling, OPTIC-4 truly excels. It accommodates a wider variety of sample types, including solids, liquids, and gases, making it highly versatile for various applications. This flexibility means that researchers no longer need to worry about sample compatibility, as the OPTIC-4 can adapt to their specific needs, whether they are working with volatile organic compounds or non-volatile substances.

"Versatility in sample handling enhances the effectiveness of our analyses across multiple projects."Additionally, the automated nature of sample preparation reduces human error and improves overall assay reproducibility, making it an asset in high-stakes research environments.

Cost-Effectiveness Over Time

While the initial investment in an OPTIC-4 system may be more significant compared to traditional setups, it becomes a cost-effective option in the long run. The increased efficiency reaps considerable savings by allowing laboratories to process more samples within the same timeframe. This advantage is particularly prominent in regulated industries where compliance necessitates frequent testing.

"In terms of long-term operation costs, OPTIC-4 pays for itself with its efficiency."As organizations recognize the value of time and resource management, they will find that adopting OPTIC-4 is a strategic move toward optimized operations.

Applications of OPTIC-4 in Various Industries

Environmental Monitoring

The OPTIC-4 system plays a crucial role in the field of environmental monitoring, offering unmatched sensitivity and accuracy for detecting volatile organic compounds (VOCs) in the atmosphere. It enables researchers and environmental scientists to conduct real-time analysis and monitoring, ensuring compliance with stringent regulations. With the ability to discern trace levels of pollutants, OPTIC-4 helps in assessing air quality, soil contamination, and water safety. This empowers industries to take proactive measures and develop sustainable practices to preserve the environment.

Pharmaceutical Applications

In the pharmaceutical sector, the usage of OPTIC-4 has transformed the way drugs are analyzed and tested. Its capability to separate, identify, and quantify complex mixtures allows for rigorous quality control in manufacturing processes. OPTIC-4 excels in the analysis of active pharmaceutical ingredients (APIs) and excipients, ensuring that all components meet required specifications. This is crucial for regulatory compliance and maintaining patient safety as it guarantees that medications are free from harmful impurities.

Food Industry Insights

The food industry benefits greatly from the advanced applications of OPTIC-4, particularly in ensuring food safety and quality. From detecting pesticide residues to analyzing flavor compounds, its reliability enables food producers to maintain high standards. The ability to monitor food freshness and classify products based on their chemical composition leads to improved consumer trust and satisfaction. The application of OPTIC-4 has been fundamental in addressing challenges such as contamination, spoilage, and product authenticity.

Key Benefits Across Industries

| Industry | Key Application | Benefits |

|---|---|---|

| Environmental | Pollutant Detection | Real-time monitoring, regulatory compliance |

| Pharmaceutical | Quality Control | Ensures safety, regulatory adherence |

| Food | Safety Analysis | Improves consumer trust, prevents spoilage |

Conclusion

As we delve into the various industries that leverage the power of the OPTIC-4 system in gas chromatography, it is evident that its applications stretch far and wide. From safeguarding our environment to ensuring the efficacy of pharmaceuticals and maintaining the integrity of our food supply, OPTIC-4 stands as a pivotal tool that advances both safety and innovation across multiple sectors. By adopting such technologies, industries are not just enhancing their operational capabilities but are also committing to higher standards of safety and quality.

Future Trends in Gas Chromatography with OPTIC-4

As the field of gas chromatography continues to advance, OPTIC-4 stands at the forefront, ready to tackle emerging challenges that demand ever more sophisticated analytical techniques. The integration of new technologies and methodologies is expected to revolutionize the way analyses are performed, enhancing both efficiency and accuracy. Here we explore potential developments and innovations that may shape the future of gas chromatography.

Increased Automation and Efficiency

The demand for high-throughput analysis in various industries is pushing for increased automation in gas chromatography. Future iterations of OPTIC-4 may incorporate:

- Automated Sample Handling: Reducing manual intervention to enhance the speed of analysis.

- Robust Data Management Systems: Implementing AI to optimize data analysis and interpretation.

- Integration with Lab Management Software: Streamlining laboratory processes for improved efficiency.

Enhancements in Sensitivity and Selectivity

Future developments in gas chromatography with OPTIC-4 are likely to focus on enhancing sensitivity and selectivity, crucial for detecting trace levels of components in complex matrices. Innovations may include:

- Advanced Detector Technologies: Incorporating next-generation detectors for improved detection limits.

- Smart Column Technologies: Deploying columns with tailored stationary phases to enhance selectivity.

- (Ultra) Fast GC Techniques: Adapting methodologies that significantly reduce analysis times without compromising data quality.

Sustainability and Environmental Considerations

As sustainability becomes a critical factor in laboratory operations, the future of gas chromatography is expected to include more eco-friendly practices. The OPTIC-4 system may evolve by:

- Reducing Solvent Consumption: Implementing techniques that minimize the use of harmful solvents.

- Energy-Efficient Operations: Designing systems that consume less power without reducing performance.

- Waste Reduction Strategies: Developing methods that decrease the generation of hazardous waste.

Integration with Emerging Technologies

The potential integration of emerging technologies is a key trend in enhancing gas chromatography capabilities. OPTIC-4 may leverage:

- Machine Learning and AI: Utilizing algorithms for predictive analytics, improving reproducibility.

- Real-Time Analysis: Enabling in-field measurements that provide immediate data analysis.

- Cloud Computing: Facilitating seamless data sharing and processing on global platforms.

In conclusion, as we look ahead, the evolution of gas chromatography with OPTIC-4 is poised to transform analytical techniques. With improved automation, sensitivity, sustainability practices, and integration with cutting-edge technologies, the future of gas chromatography promises enhanced analytical capabilities that meet the growing demands of various industries. The continuous pursuit of innovation will ensure that OPTIC-4 remains a pivotal player in this dynamic field.

Conclusion

In summary, the integration of OPTIC-4 technology in gas chromatography presents numerous advantages that elevate the capabilities of modern analytical labs. Its unique features not only enhance the precision and efficiency of analyses but also significantly reduce the turnaround time for results, paving the way for more informed decision-making in various fields, including pharmaceuticals, environmental studies, and food safety.

Moreover, the flexibility of the OPTIC-4 system allows for seamless adaptation to existing setups, making it an appealing choice for many organizations looking to improve their analytical performance without incurring excessive costs. The combination of high sensitivity, ease of use, and minimal maintenance makes it a worthwhile investment for those who prioritize accuracy in their work.

As we reflect on the impact of these advancements in gas chromatography, it becomes evident that embracing technologies like OPTIC-4 is crucial for staying competitive and compliant in today's rapidly evolving market. We encourage you to delve deeper into how OPTIC-4 can transform your analytical processes and to consider its potential for enhancing the quality of your results.

Are you ready to take the next step in revolutionizing your laboratory processes? Explore the capabilities of OPTIC-4 and discover how it can benefit your organizational goals.

FAQs

What is the purpose of this blog?This blog aims to provide informative content on a variety of topics, helping readers gain insights and knowledge that they can apply in their everyday lives.

Who is the target audience for this blog?The target audience includes individuals who are seeking to enhance their understanding of specific subjects, ranging from beginners to experts in various fields.

How often is new content published?New content is published regularly, typically on a weekly basis, to ensure that readers have access to fresh and relevant information.

Can I contribute to the blog?Absolutely! We welcome guest contributions. If you have a topic in mind, please reach out through our contact page to discuss potential collaboration.

How can I stay updated with the latest posts?You can subscribe to our newsletter or follow us on social media platforms to receive notifications whenever new content is posted.

Is there an option to leave comments or feedback on the posts?Yes! Readers are encouraged to leave comments and feedback on each post, fostering discussion and community engagement.

What should I do if I have a question that isn’t answered here?If you have any additional questions, feel free to contact us directly via our contact page or leave a comment on the relevant post!